- VECTRIC CUT2D PASS DEPTH HOW TO

- VECTRIC CUT2D PASS DEPTH UPDATE

- VECTRIC CUT2D PASS DEPTH PROFESSIONAL

VECTRIC CUT2D PASS DEPTH PROFESSIONAL

Robert Davis has used the technique to machine a fabulous permanent momento for his mother-in-law, and added a professional finish by adding a frame and back-light. No wood preparation before cutting after which I stained it, let it dry for 24 hours, sanded it and finally finished it with 3 coats of gloss poly." "The machining was done with a 90 degree 1/4 inch V-Bit with a carving depth of 0.030" at a resolution of 408 lines and a line angle of 33 degrees. "My latest project was engraved for my next door neighbor and is a picture of his 7 Year old daughter." Neil has been carving portraits with PhotoVCarve and the results have been excellent. Jeff at Guernsey Wood Carvers has used the PhotoVCarve groove machining process to engrave a special gift for a friend to remember their beloved pet. He has been experimenting with 'night-lights' to make the lithophanes spring to life. This machining process significantly reduces the cutting times and gives fantastic results.Īlso known as - calgrdnr - on the Vectric Forum is using the single pass technique pioneered by Bill Schober to engrave lithophanes of his family and friends. Pretty simple!"īill has also been busy perfecting the process of cutting lithophanes in a Single Pass using a V-bit or engraving cutterwithout first running a roughing pass. Then print and glue the transparency to the back of the lithophane being sure to line it up just right. First I convert the color image into a CMYK image then delete the "K" channel which is the black or shades of gray that the lithophane already represents.

"I use HP color transparency film to add the colour to my lithophanes. Creating a Form cutter is discussed in the section on Using Form Cutters immediately following this section on the Tool Database. "My Wife likes them so that's all that counts :)"īill Schober has developed a fantastic process for adding colour to lithophanes which makes the results even more stunning. George - Lovebugjunkie - on the Vectric Forum has also been engraving great lithophanes and commented, Then adds a few clear coats to seal to the frame and also to the corian, which brings a nice luster to the lithophane. Greg sandwiches the lithophanes between the two cutouts of mdf, paints the text using regular acrylic paints. 128 deep cut with one pass (as described above).When cutting the lithophanes Greg uses a 0.125" diameter ball nose for the roughing toolpaths and a 0.0625 diameter ball nose with 15% stepover for the finishing. This being said, I don't understand how it can do my. 25 to cut a 1" deep hole, it will make 4 passes. Shouldn't it read "the maximum depth the tool can cut with each pass"? It does go on the say if you put a pass depth of. If I read that sentence only.I would interpret that as the depth the tool is physically capable of cutting. To confuse things even further when I looked up the definition of pass depth in the Vcarve help file it defines the pass depth as "the maximum depth of cut the tool can cut". 128 and it's telling me it will do it with 1 pass? Since my pass depth is less than the cut depth, how is it going to accomplish that in 1 pass?

VECTRIC CUT2D PASS DEPTH UPDATE

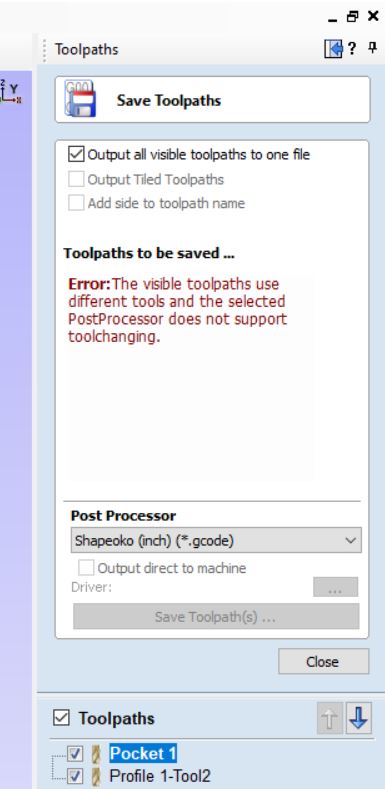

Is this the update you were talking about?Įven if that fixes that problem, I must still be misinterpreting the pass depth/cut depth because I am working on a new project now and I put a pass depth of. Thanks.I didn't have the latest version but just got it. 125 inch deep cut and it cut it perfectly.

5 deep cut) and the other with a pass depth of. I redid the entire job but this time I set up a separate tool for each cut.one with the pass depth of. 125 inch deep just shy of.25 inch deep! This makes no sense to me. 5 inch deep cut.but overall cut it quite a bit deeper than the. instead it cut both areas deeper than both cut depth settings. 125 inch deep cut and would certainly only cut it. 25) I figured the cut depth would over-ride the pass depth setting on the. 5 cut but chose the same tool for both cuts (the one with the pass depth of. I made two separate toolpaths.one for the. My question is.I needed to cut two different depths, one at.

VECTRIC CUT2D PASS DEPTH HOW TO

I did not see any way to start a new question so if anyone can lead me in the right direction on how to post a question on this ease do. Hello, I'm new at the forum AND cnc routing.I know nothing about either so I'm not really sure if I'm posting this correctly but I did a search on my problem and this was the closest subject I found.

0 kommentar(er)

0 kommentar(er)